RISE OF SPACE BIOMANUFACTURING

Increasing access to space is bringing increasing public and private efforts to leverage the unique environment of microgravity to enhance biological processes and production methods. Promising capabilities in pharmaceuticals, materials science, and regenerative medicine are being unlocked. Increased access to space will expand activity in this area and bring benefits to human health on Earth.

Microgravity conditions aboard space platforms are a setting where biological organisms and systems can behave differently as they aren’t contending with gravitational pull. For example, protein crystallization happens more uniformly, and delicate tissue can grow without being pulled out of shape. As the transition from space-based research being limited to government space stations to sustained commercial operations in low Earth orbit (LEO) occurs, the resulting innovations are poised to address critical challenges on Earth. These include producing advanced biomaterials, developing more effective pharmaceuticals, and creating resilient supply chains for essential medical products.

PIONEERING LABS: BIOTECH STARTUPS IN MICROGRAVITY

Work in space biomanufacturing is already off to a strong start and is exemplified by several case studies:

Varda Space Industries - drug formulation in microgravity

LambdaVision - space-based manufacturing of artificial retinas

Redwire Space - 3D bioprinting & tissue engineering in microgravity

Axiom Space - commercial space stations to include biomanufacturing capability

Blue Origin - the Orbital Reef commercial space station with biomanufacturing potential

Eascra Biotech - nanomedicine for challenging therapeutic delivery

Ambrosia Space Manufacturing Corporation - biomanufacturing in microgravity

Voyager Space - building the future of commercial space stations & biomanufacturing

Vast Space - space habitats for microgravity biomanufacturing

Varda Space Industries: Drug Formulation in Microgravity

Varda Space was founded by Will Bruey and Delian Asparouhov in 2021 to manufacture in microgravity and bring those products back to Earth. Bruey had been an engineer at SpaceX and Asparouhov is a partner at Founders Fund. Varda has raised $141 million over five rounds. They have revenue in the form of government contracts for testing and have already successfully completed two space missions.

Varda developed and built a small, 300 kg, spacecraft that can be launched to space, complete autonomous manufacturing, and return to Earth with products intact. The first mission was groundbreaking in several ways:

The W-1 spacecraft launched to space on a SpaceX Falcon 9 rocket in June 2023 marking the first commercial in-space pharmaceutical manufacturing effort.

While in space, the antiviral drug ritonavir was made into a more soluble form, called form III crystals. Currently this medication needs to be formulated with additives to be absorbed in the stomach because it has a tendency to form sediment. Without gravity, this sediment doesn’t form and so the more soluble form can be made with stability.

In February 2024, W-1 had a successful re-entry and landing in Utah, making it the first commercial spacecraft to land on US soil.

Upon return, the Ritonovir was found to have retained its soluble form III crystals.

Varda's accomplishment marks a significant milestone in pharmaceutical manufacturing, suggesting that the microgravity environment can be harnessed to produce drug formulations with enhanced properties that are difficult or impossible to achieve on Earth.

Building on that success, Varda just completed their second mission:

Varda’s W-2 spacecraft was launched by SpaceX in January 2025 and successfully made the first commercial landing in Australia.

This mission included a spectrometer to take measurements for hypersonic testing during re-entry under a $48 million contract with the Air Force Research Lab. A heat shield thermal protection system designed in collaboration with NASA was used. Pharmaceutical equipment was also included and for testing.

Varda shows promise with early technological success in space missions and two product lines: drug formulation capability not available on Earth and re-entry capsules capable of withstanding hypersonic speeds allowing for testing.

LambdaVision: Space-Based Manufacturing of Artificial Retinas

LambdaVision was founded in 2009 by Dr. Robert Birge and Dr. Nicole Wagner from the University of Connecticut. They are at the forefront of developing an artificial retina to restore vision in patients with retinal diseases like retinitis pigmentosa and macular degeneration. The company has used the microgravity environment via the International Space Station (ISS) to enable to necessary fine tissue building. The company received a $5 million dollar grant from NASA to support its work and, in May 2024, completed a seed round led by Aurelia Foundry Fund, as well as receiving investment from Connecticut Innovations. They’ve received an estimated $17 million in total grants and investments.

The production of LambdaVision's artificial retina involves a meticulous layer-by-layer assembly of approximately 200 ultra-thin layers of the light-sensitive protein bacteriorhodopsin. On Earth, gravitational forces can cause sedimentation and convection, leading to inconsistencies in these layers; microgravity conditions minimize these effects, resulting in more uniform and stable layer formation, which is crucial for the implant's performance.

LambdaVision has completed multiple missions to the ISS to refine and validate its manufacturing process:

In December 2018, the first experiment demonstrated the feasibility of layer-by-layer assembly in microgravity.

In December 2021, additional research successfully produced four films, one of which reached the target of 200 layers, validating the layer-by-layer manufacturing process in microgravity.

In April 2022, improved hardware automation and in-orbit process controls, leading to the development of 10 test retinas that were returned to Earth for analysis. Goals included ensuring that the delicate layering process remained intact during and after the microgravity exposure, verifying that the bacteriorhodopsin protein retained its light-sensitive properties essential for mimicking photoreceptor functions, and assessing the consistency and evenness of the protein layers, which is crucial for optimal retinal performance.

In January 2024, evaluated the transport of bacteriorhodopsin in powdered form to the ISS to help the manufacturing process for scalability. Previously, the protein was sent in solution which could degrade over time, especially under varying environmental conditions, and required special handling to avoid psillage and contamination. The shift to a powdered form aimed to address those issues because powdered proteins are less susceptible to degradation and more robust in storage, and powder reduces the volume and weight of the payload. During the mission, the powdered bacteriorhodopsin was successfully reconstituted into solution aboard the ISS. It was tested to ensure the reconstituted protein was free from contaminants and retained the critical light-absorbing capabilities. This was considered a crucial step toward scalable production of artificial retinas in space

With a building track record and solid funding, LambdaVision is poised to transition from research to clinical applications, offering hope to millions affected by retinal disease.

Redwire Space: 3D Bioprinting & Tissue Engineering in Microgravity

Redwire Space was established in 2020 by the private equity firm AE Industrial Partners and has become a leader in space infrastructure manufacturing. The company's formation was marked by the merger of Adcole Space and Deep Space Systems. Peter Cannito was appointed as Chairman and CEO. Cannito had been CEO of Polaris Alpha and served as an officer in the U.S. Marine Corps.

A significant milestone in Redwire's development in biomanufacturing was the June 2020 acquisition of Made In Space. Founded in 2010 by Aaron Kemmer, Jason Dunn, Michael Snyder, and Mike Chen, Made In Space was known for its advancements, including the first 3D printer operated in microgravity. In 2023, the company successfully secured a NASA award under the VITAL program to advance bioprinting capabilities in space.

Redwire's BioFabrication Facility (BFF) is a state-of-the-art 3D bioprinter designed for microgravity conditions aboard the ISS. The microgravity environment allows for the assembly of complex tissue structures without the need for scaffolding, which is reasonably expected to unlock breakthrough products for regenerative medicine and organ transplantation.

The company has expanded its capabilities into multiple areas, including recent entry into defense, via a series of acquisitions:

Made in Space, Inc. acquired in June 2020 to incorporate advanced in-space manufacturing and assembly technologies, including 3D printing capabilities.

Roccor acquired in October 2020 to add expertise in deployable structures such as solar panels, antennas, and booms.

LoadPath acquired in December 2020 adding mechanical, structural, and thermal technologies for satellite and launch applications for engineering and testing services.

Oakman Aerospace acquired in January 2021 added modular open system architectures and satellite design, facilitating scalable and customizable space systems.

Deployable Space Systems acquired February 2021adding advanced deployable solar array systems.

QinetiQ Space NV acquired October 2022 expanded satellite design and development expertise, particularly in collaboration with European space agencies.

Hera Systems acquired August 2024 enhanced capabilities in spacecraft development for national security missions, supporting specialized operations in geostationary orbit.

Edge Autonomy acquired January 2025 for a significant expansion into defense with uncrewed aerial system technologies, aligning satellite capabilities with drone operations.

Redwire went public via SPAC in September 2021 with a valuation of $620 million. Revenue growth has been good, and current valuation is $1.14 billion.

Redwire’s ISS Bioprinting Missions:

July 2019 - First test of the BFF on ISS. Successfully demonstrated that human heart cells could be bioprinted in microgravity.

December 2020 - ISS experiment tested bioink formulations for stability in space. Results showed that bioprinted tissues maintained structural integrity post-flight when returned to Earth.

August 2022 - First attempt at printing human knee meniscus tissue. This was done under a DOD grant focused on developing regenerative treatments for injuries suffered by military personnel.

March 2023 - Developed a technique to condition bioprinted tissues in microgravity before returning them to Earth for further growth. This helps improve cell viability and tissue formation, a critical step toward creating full-scale human tissues.

December 2023 - BFF upgrades included new automation capabilities for more precise tissue layering and improved fluid handling in microgravity.

As a part of a broad set of space and defense capabilities, Redwire has positioned itself as a key player in space-based production for regenerative medicine, including lab grown replacement organs.

Axiom Space: Commercial Space Stations to Include Biomanufacturing Capability

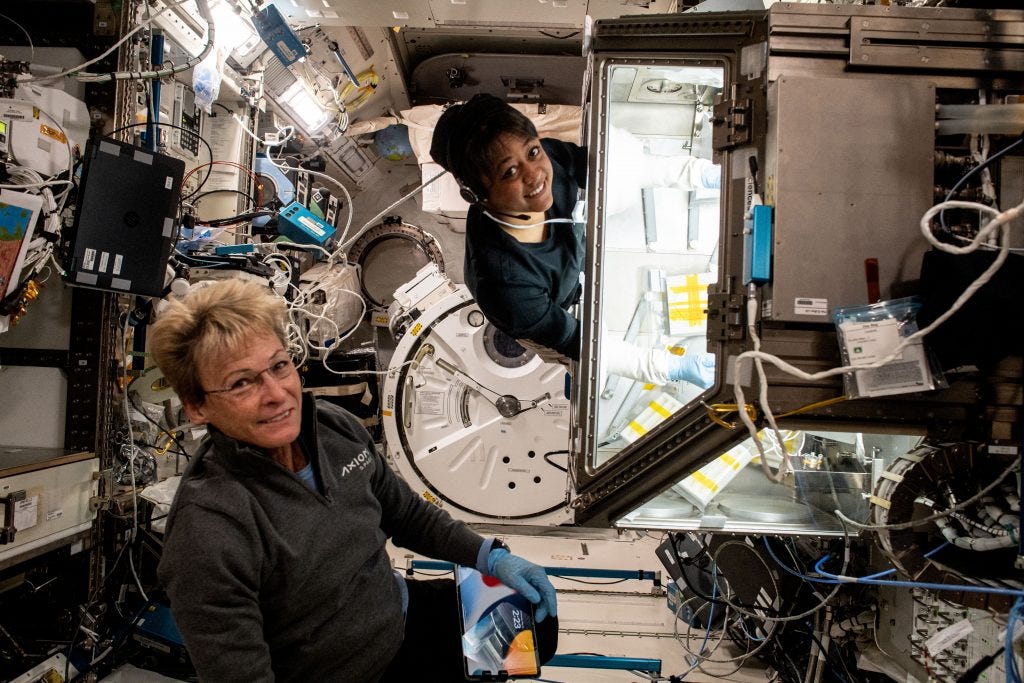

Axiom Space was founded in 2016 by Michael Suffredini and Kam Ghaffarian to build the world’s first commercial space station, providing dedicated research and manufacturing capabilities in LEO. Suffredini was the NASA ISS Program Manager from 2005 to 2015. Ghaffarian previously founded Stinger Ghaffarian Technologies, a major NASA contractor that was sold to KBR in 2018. Axiom was selected by NASA to provide the first commercial destination module on the ISS and has completed research in space to develop future in-space manufacturing of biomedical products.

Axiom has raised $500 million over six rounds, including its last $350 million series C round in August 2023. The company has an estimated total of $2.2 billion in customer contracts.

Axiom’s broad space station capability set includes a focus on leveraging microgravity to develop next-generation tissue engineering, regenerative medicine, and pharmaceutical manufacturing techniques:

The Ax-2 mission in May 2023 conducted four biomanufacturing experiments, including drug crystallization studies and regenerative tissue research.

A partnership with Wake Forest Institute for Regenerative Medicine (WFIRM) to develop vascularized bioengineered liver and kidney tissues to improve transplant-ready tissue constructs in space.

A new biomanufacturing bub in Winston-Salem, NC partnering with WFIRM and RegenMed Development Organization to establish a ground-based R&D center for in-space regenerative medicine manufacturing.

Axiom has completed three manned missions to the ISS:

Ax-1 in April 2022 was the first fully private crewed mission to the ISS.

Ax-2 in May 2023 carried biomanufacturing payloads and was a Saudi-funded mission.

Ax-3 in January 2024 hosted an international crew from Italy, Turkey, and Sweden, and conducted additional biopharma and material science research.

The Axiom Payload Power Thermal Module (PPTM) is Axiom’s first stage: adding a commercial module to the ISS. The module is designed to host microgravity research, biomanufacturing, and advanced materials production. The module is scheduled to launch in 2026 and attach to the ISS before transitioning into an independent commercial station after the ISS is decommissioned. The module will provide dedicated lab space, improved life support systems, and manufacturing infrastructure for pharmaceutical, biotech, and materials companies.

If successful, Axiom’s space station could serve as the premier platform for microgravity-based research and development.

Blue Origin: The Orbital Reef Commercial Space Station with Biomanufacturing Potential

Blue Origin was founded in 2000 by Jeff Bezos, the founder of Amazon. Blue Origin is a developing full spectrum launch and space company. In collaboration with Sierra Space, Blue Origin is spearheading the development of Orbital Reef, a commercially owned and operated space station intended to serve as a "mixed-use business park" in LEO. The development of Orbital Reef is projected to cost approximately $100 billion.

Orbital Reef is designed to facilitate a diverse range of commercial activities, including biomanufacturing. By providing state-of-the-art infrastructure and services, Orbital Reef aims to attract biotech companies and research institutions to conduct cutting-edge biomanufacturing processes in space.

The Orbital Reef project involves a group of industry leaders:

Sierra Space is developing the Large Integrated Flexible Environment (LIFE) habitat, a module that provides providing expansive, customizable space for various commercial uses, including biomanufacturing.

Boeing is designing and developing the station's science module.

Redwire Space is providing microgravity research capabilities and manufacturing technology to support biomanufacturing and other industrial activities on the station.

Progress has been made developing Orbital Reef's life support systems:

Life support system testing in March 2024 completed critical testing milestones for systems designed to provide clean air and water.

Structural integrity validation in July 2024 conducted a full-scale burst pressure test on the LIFE habitat structure, ensuring the module's safety and durability in space conditions.

Orbital Reef is planned to become operational by 2030. A successful Orbital Reed would lower the barriers to entry for various industries, fostering innovation and economic growth in space, including in biomanufacturing.

Eascra Biotech: Nanomedicine for Challenging Therapeutic Delivery

Eascra Biotech was founded in 2021 by Mari Anne Snow and Dr. Yupeng Chen. Eascra is a nanomedicine company that specializes in developing innovative therapeutic delivery systems, based on Janus Base Nanoparticles, designed to target hard-to-penetrate tissues, including articular cartilage, kidneys, and tumors. Snow brought prior business experience and had founded several companies before Eascra. Chen is a professor and lab director at the University of Connecticut and an expert in nanomedicine and biomedical engineering.

Eascra is funded by a $1.8 million NASA grant and backed by accelerator and incubator support.

Eascra is commercializing therapeutic delivery via the Janus Base Nanoparticle platform. Inspired by DNA, Janus particles are synthetic molecules capable of fully encapsulating therapeutic cargoes, ensuring stability at room temperature while maintaining bioactivity over extended periods. These particles can deliver a wide range of therapeutic agents, including siRNA, mRNA, Cas9 proteins, peptides, and other drug molecules. The platform can address critical medical needs such as osteoarthritis treatment, cartilage regeneration, and tumor treatment via targeted delivery which would reduce systemic exposure and minimize patient effects.

Eascra Biotech has completed research that supports the potential of microgravity to allow improved self-assembly of Janus particles. Eascra successfully launched its Janus technology into space in 2023 and 2024 to study the effects of microgravity on nanomaterial fabrication and therapeutic delivery.

In May 2023, during the Axiom Mission 2 (Ax-2), Eascra conducted experiments to fabricate Janus Base Nanomaterials in microgravity on the ISS. The primary objective was to assess whether the absence of gravity-induced sedimentation could enhance the homogeneity and structural integrity of the nanoparticles. Preliminary results indicated that microgravity conditions facilitated a more uniform self-assembly process, leading to improved material properties compared to Earth-based fabrication.

Eascra launched a second experiment in March 2024 aiming to scale up the production of Janus Base Nanoparticles and further validate the advantages of microgravity-assisted fabrication. Published results from this mission are pending.

In July 2024, Eascra was selected for the ISS National Lab's Igniting Innovation program. This initiative focuses on studying the application of Janus Base Nanoparticles in targeted cancer treatment delivery, particularly for solid tumors like breast and ovarian cancers.

The promising initial results these space-based experiments shows both promise for Eascra Biotech and for microgravity as an enabler for new beneficial medical technology.

Ambrosia Space Manufacturing Corporation: Biomanufacturing in Microgravity

Ambrosia Space is a new company, formed in 2024, with a mission to biomanufacture in space and aid the settlement of Mars. The company was founded by Mario Maggios who had worked as an aerospace engineer, including on the IM-1 Lunar Lander at Intuitive Machines and on spacecraft life support systems at Paragon Space. The stated mission of the company is to bring biomanufacturing to microgravity to make better biopharmaceuticals here on Earth and advance humankind's ability to explore and settle the solar system.

Voyager Space: Building the Future of Commercial Space Stations & Biomanufacturing

Voyager Space was founded in 2019 with a vision to create a vertically integrated commercial space infrastructure company, accelerating the commercialization of LEO. In support of that vision, Voyager has strategically acquired seven space companies: Altius Space Machines, Pioneer Astronautics, The Launch Company, Nanoracks, Valley Tech Systems, Space Micro, and ZIN Technologies. Nanoracks, a Voyager Space subsidiary as of 2020, remains at the forefront of biomanufacturing and microgravity research.

Nanoracks was founded in 2009 by Jeffrey Manber and Charles Miller. The company is a leading provider of commercial access to space, enabling a range of in-space services including satellite deployment, microgravity research, and development of space infrastructure. Manber had been managing director of Energia USA and at MirCorp. Miller came as an experienced space entrepreneur, including having co-founded and led Lynk Global.

Voyager raised almost $180 million over five rounds. Nanoracks was awarded a $160 million NASA Commercial LEO Destinations (CLD) contract to develop Starlab as a replacement for the ISS. The subsidiary has been profitable, with revenues exceeding $50 million annually. Voyager Space filed for IPO in January 2025; the number of shares to be offered and the price range have not yet been released.

Nanoracks has been at the forefront of facilitating biomanufacturing research in microgravity environments:

Microgravity Research Platforms: The company provides standardized research platforms aboard the ISS, allowing researchers to conduct experiments in microgravity with ease. These platforms have been utilized for a variety of biological and pharmaceutical studies, including protein crystallization and cell culture experiments.

Bishop Airlock Module: Launched in December 2020, the Bishop Airlock is the first commercially funded airlock module on the ISS. It expands the station's capabilities by allowing larger payloads to be moved inside and outside the station, facilitating increased research opportunities in areas such as biomanufacturing.

Nanoracks has had a number of successful missions and collaborations:

CubeSat Deployments: Nanoracks has successfully deployed over 1,300 small satellites, including CubeSats, from the ISS. These deployments have supported various research initiatives, some focusing on biological sciences and Earth observation.

Educational and Research Partnerships: For example, Nanoracks partnered with biotechnology startups to study the effects of microgravity on biological organisms, contributing to advancements in biomanufacturing processes.

Nanoracks has facilitated numerous significant biological science experiments aboard the ISS with examples including:

Protein Crystal Growth Studies: In 2018, Nanoracks supported a professional protein crystal experiment aimed at enhancing drug development processes.

Student-Designed Biological Research: Nanoracks enabled student-designed experiments on the ISS. For instance, in 2012, the company facilitated life science experiments to better understand how spaceflight affects the human body, as well as the growth of cells and plants.

Microbial and Cellular Studies: In 2024, as part of the Student Spaceflight Experiments Program (SSEP), Nanoracks facilitated experiments focusing on protein and bacterial interactions. These studies aimed to promote healthy crew members by understanding microbial behavior in microgravity.

Regenerative Medicine Research: Nanoracks supported studies on flatworm regeneration conducted in space providing insights into tissue regeneration processes.

Through these and other initiatives, Voyager Space continues to advance biological sciences by leveraging the unique environment of space, as a key component of a broader commercial LEO provider. The Starlab Space Station, to be built in collaboration with Lockheed Martin, is intended to serve as a hub for research, manufacturing, and tourism and is projected to be operational by 2027.

Vast Space: Space Habitats for Microgravity Biomanufacturing

Vast was founded in 2021 by Jed McCaleb, an entrepreneur known for co-founding Ripple and Stellar, with the vision of creating artificial gravity space stations to support long-term human habitation and commercial research. The company is developing Haven-1, the first private microgravity research and manufacturing platform, slated for launch in August 2025.

The company is privately funded by founder Jed McCaleb, who committed an estimated $500 million to Vast’s development. They have a strategic partnership with SpaceX, securing Falcon 9 as the launch vehicle for Haven-1. They are developing future expansion modules with a goal of launching a full-scale artificial gravity space station by the 2030s.

Vast is actively integrating biomanufacturing and pharmaceutical research into its upcoming Haven-1 microgravity lab:

Microgravity-Enabled Bioprocessing - Haven-1 will offer dedicated facilities for pharmaceutical crystallization, protein folding, and biomaterial production, capitalizing on the superior structural properties that form in space.

Advanced Space Experiment Processor 4 (ADSEP4) - Developed in partnership with Redwire Space, this fully automated small-batch bioprocessing unit will enable protein-based drug formulation, tissue engineering, and cell culture growth in orbit.

Vast issued a joint request for proposals with SpaceX to attract universities, biotech firms, and drug companies looking to develop new drug formulations and biomaterials in space.

Vast is setting the foundation for scalable in-space manufacturing, leveraging Haven-1 as a commercial microgravity research platform. If successful, its future artificial gravity station could revolutionize long-term space habitation and industrial biomanufacturing.